Landing your dream job as an advanced manufacturing engineer requires thorough preparation and a deep understanding of the field. This comprehensive guide meticulously crafted with SEO optimization in mind delves into 30 crucial interview questions and provides insightful answers that will equip you to impress your potential employer.

Mastering the Art of the Interview: A Comprehensive Guide for Advanced Manufacturing Engineers

In today’s dynamic and competitive manufacturing landscape, advanced manufacturing engineers are highly sought-after professionals who play a pivotal role in driving innovation, efficiency, and quality To secure a coveted position in this field, it’s imperative to be well-prepared for the interview process This comprehensive guide, meticulously crafted with SEO optimization in mind, provides you with the essential knowledge and insights to answer 30 critical interview questions with confidence and clarity.

Navigating the Interview: Essential Tips for Success

Before the Interview

- Thoroughly research the company and the specific position you’re applying for. This will demonstrate your genuine interest and understanding of the company’s goals and values.

- Practice answering common interview questions. This will help you articulate your thoughts clearly and confidently during the interview.

- Prepare questions to ask the interviewer. This shows your proactive nature and genuine interest in the company and the role.

During the Interview:

- Dress professionally and arrive on time. First impressions matter, so make sure you present yourself in a positive light.

- Be confident and enthusiastic. Show the interviewer that you’re passionate about advanced manufacturing engineering and eager to contribute to the company’s success.

- Listen attentively to the interviewer’s questions and answer them directly and concisely. Avoid rambling or going off on tangents.

- Highlight your relevant skills and experience. Use specific examples to demonstrate how you’ve applied your knowledge and skills in previous roles.

- Be prepared to discuss your salary expectations. Do your research beforehand to determine a fair and competitive salary range for the position.

After the Interview:

- Thank the interviewer for their time. Send a follow-up email reiterating your interest in the position and thanking them for the opportunity to interview.

30 Advanced Manufacturing Engineer Interview Questions and Answers:

1. Can you describe a time when you successfully implemented a cost-effective manufacturing process?

This question is aimed at delving into your problem-solving skills and your ability to innovate. Manufacturing is all about efficiency and cost-effectiveness; hence, your potential employer wants to ensure that you have the skills to identify areas of improvement, develop a plan, and implement changes that will ultimately benefit the company’s bottom line. They’re looking for evidence of your strategic thinking and your ability to make a tangible difference.

Example

“In one of my projects, I noticed that our assembly line was producing a significant amount of waste. After performing a thorough analysis, I found out the main cause was an outdated machine. I proposed investing in a new, more efficient model which would reduce waste and improve productivity. The initial cost was high but after presenting a detailed ROI analysis to management, they approved it. Post-implementation, we saw a 30% reduction in waste and a 15% increase in output. This not only made the process more cost-effective but also improved overall efficiency.”

2. How have you utilized CAD software for designing manufacturing systems in your past roles?

The essence of this question is to gauge your hands-on experience and expertise with Computer-Aided Design (CAD) software, a key tool in modern manufacturing engineering. It’s about understanding how you’ve used this technology to create efficient, effective manufacturing systems. The interviewer wants to assess your technical skills, creativity, problem-solving abilities, and your understanding of how to use technology to drive improvements in manufacturing processes.

Example:

“In my experience, CAD software has been instrumental in designing manufacturing systems. I’ve used it to create detailed 3D models of production lines which allowed me to visualize the entire process and identify potential bottlenecks or inefficiencies. I also utilized its simulation capabilities to test different configurations and optimize the system before actual implementation. This not only saved time but also reduced costs associated with trial-and-error methods. Moreover, by integrating CAD with other tools like FEA (Finite Element Analysis), I was able to perform stress analysis on parts to ensure their durability under operational conditions. Overall, CAD has been a powerful tool for me in creating efficient, cost-effective, and reliable manufacturing systems.”

3. Can you share an experience where you had to troubleshoot a complex production issue?

Manufacturing processes are complex, and when something goes wrong, it can be a costly issue in terms of both time and resources. Companies want engineers who can not only troubleshoot these issues, but also understand and address the root cause to prevent similar problems in the future. This question helps the interviewer assess your analytical skills, problem-solving ability, and experience with production challenges.

Example:

“In one instance, a critical production line was experiencing frequent downtime due to an unidentified issue. I initiated a cross-functional team with quality, maintenance and operations staff to investigate the problem. We used root cause analysis methods like fishbone diagrams and 5 Whys to identify potential causes. It turned out that two separate issues were causing the breakdowns – a mechanical fault in one of the machines and an error in the assembly process. I coordinated the repair for the machine and retrained the operators on the correct assembly procedure. This significantly reduced the downtime and increased our overall productivity.”

4. How do you ensure safety standards are met while designing and implementing manufacturing processes?

Safety is of utmost importance in manufacturing operations. Accidents or mishaps can cause serious harm, not to mention the potential for significant financial losses and regulatory penalties. Therefore, hiring managers want to know that you prioritize safety and have a clear strategy to ensure all processes and designs comply with safety regulations. They are looking for evidence that you understand and respect the importance of creating a safe work environment.

Example:

“Ensuring safety standards in manufacturing processes begins with a thorough understanding of regulations like OSHA and ISO. I incorporate these guidelines during the design phase itself. Risk assessments are crucial for identifying potential hazards. By conducting regular audits, we can ensure compliance and identify areas for improvement. Employee training is another key aspect. Educating staff about safe practices reduces accidents and improves overall productivity. Continuous monitoring and updating processes based on new technologies or changes in regulations also plays an important role in maintaining safety standards.”

5. Can you elaborate on your experience with additive manufacturing technologies?

Additive manufacturing technologies, such as 3D printing, are steadily transforming the field of manufacturing engineering. These technologies allow for faster prototyping, more complex designs, and even the creation of end-use parts. Therefore, hiring managers are keen to understand your experience and proficiency in this area, to ensure you can contribute effectively to the evolution of their manufacturing processes.

Example:

“I have a strong background in additive manufacturing technologies, particularly 3D printing. I’ve worked extensively with different materials such as metals and polymers, understanding their properties and how they interact during the manufacturing process. My experience also includes optimizing design for additive manufacturing (DFAM), ensuring that parts are designed efficiently for 3D printing. This involves considering factors like build orientation, support structures, and post-processing requirements. Moreover, I’ve been involved in developing quality control processes to ensure consistency and reliability of printed parts. This has often included non-destructive testing methods and statistical analysis. Overall, my expertise lies in leveraging these technologies to improve production efficiency, reduce costs, and accelerate product development cycles.”

6. What are the key factors you consider when designing a layout for a new production line?

As the brains behind the layout of a new production line, an advanced manufacturing engineer is expected to consider a myriad of factors that ensure efficiency, safety, and cost-effectiveness. These factors include the flow of materials, space utilization, worker safety, and convenience. By posing this question, hiring managers aim to gauge your understanding of the complexity of the task, your ability to prioritize effectively, and your attention to detail in regard to the many variables involved in production line design.

Example:

“When designing a layout for a new production line, I consider several key factors. The first is the workflow. It’s crucial to ensure that the process flows smoothly from one stage to the next without any bottlenecks or interruptions. Space utilization is also important. The layout should make efficient use of available space while allowing room for future expansion. Safety and ergonomics are another priority. Equipment and workstations must be arranged in a way that minimizes risk and promotes worker comfort and efficiency. Lastly, flexibility is essential. The layout needs to accommodate changes in product design, order volume, or manufacturing processes.”

7. What strategies do you use to keep up with emerging trends in advanced manufacturing?

Staying ahead of the curve is key in the world of advanced manufacturing. As technologies and techniques evolve, so too should your knowledge and skillset. A potential employer wants to see that you’re proactive about staying informed, and that you’re able to adapt and implement these new advancements to improve efficiency, productivity, and overall business outcomes.

Example:

“Staying current with advanced manufacturing trends involves a mix of continuous learning and networking. I regularly attend industry conferences, webinars, and workshops to gain insights from thought leaders. I also subscribe to relevant trade publications and follow influential figures on social media for real-time updates. Participating in online forums and communities has proven beneficial as well. Moreover, I invest time in learning new software tools and

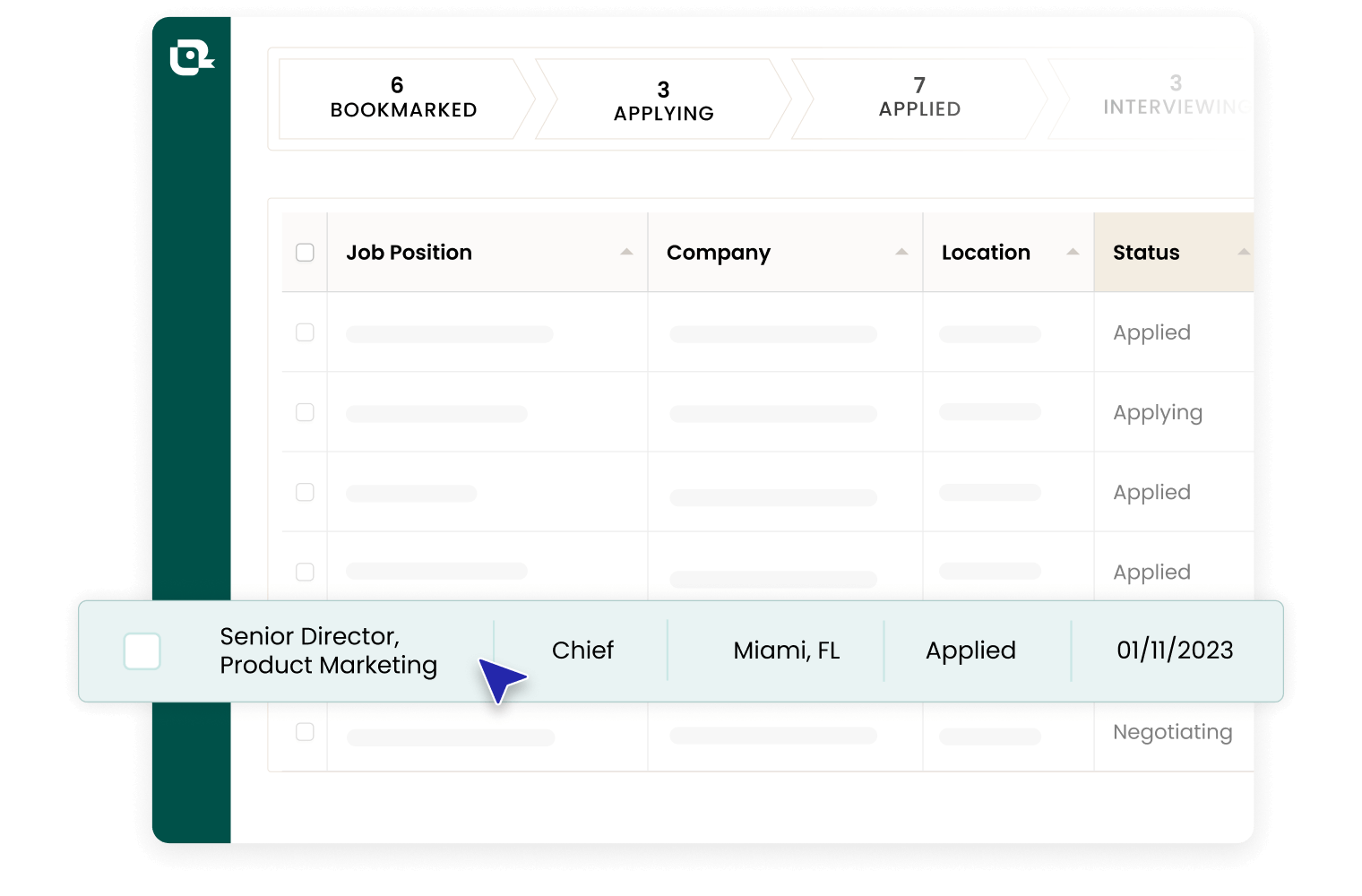

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Interviewing as a Manufacturing EngineerNavigating the path to becoming a Manufacturing Engineer involves more than just technical expertise; it requires demonstrating your ability to optimize processes, solve complex problems, and contribute to the efficiency of production systems. Interviews for this role are designed to assess a broad spectrum of your skills, from your technical acumen to your project management capabilities and interpersonal skills. In this guide, we’ll dissect the array of questions you may encounter when interviewing for a Manufacturing Engineer position. We’ll break down the significance of each question type, from technical to behavioral, and provide insight into crafting responses that showcase your qualifications. You’ll learn how to prepare effectively, what distinguishes a top-tier candidate, and the strategic questions to ask your interviewers. Armed with this knowledge, you’ll be poised to make a strong impression and take a decisive step toward securing your role in the field of manufacturing engineering.

- Find out everything you can about the company and how its products are made. Learn about its products, the technologies it uses to make them, and its place in the market. After reading this, you’ll be able to tailor your responses to fit their needs and problems.

- Make sure you understand basic engineering ideas like process design, lean manufacturing, Six Sigma, and quality control by going over Engineering Fundamentals and Best Practices. Prepare to talk about how you’ve used these ideas in previous jobs.

- Expect Technical Questions: You can expect technical questions about manufacturing equipment, CAD/CAM software, automation, and material science. Be ready to explain complex concepts clearly and concisely.

- Think about past projects and results: Be ready to talk about specific projects you’ve worked on, problems you’ve encountered, and outcomes you achieved. Set up your answers with the STAR method (Situation, Task, Action, Result).

- Know About the Latest Trends in Manufacturing: Keep up with the newest trends in manufacturing, like Industry 4. 0, additive manufacturing, and sustainability practices. Employers will be interested in how creative you are and how well you can use new technologies.

- Prepare Thoughtful Questions: Think of questions that show you’re interested in the job and the company. Inquire about their manufacturing challenges, team dynamics, or recent initiatives.

- Practice with Mock Interviews: Have friends, mentors, or coworkers help you practice interviews. This will help you improve your answers, talk to people better, and feel more confident.

By following these steps, youll be well-equipped to engage in a meaningful dialogue about how you can contribute to the companys manufacturing objectives. Your preparation will show that youre not only knowledgeable but also genuinely interested in making a positive impact as a Manufacturing Engineer.