In the world of telecommunications, cable splicers play a vital role in ensuring our digital connections are seamless and dependable. Whether you’re a seasoned pro or just starting out, landing a new job as a cable splicer means showcasing your technical expertise, problem-solving abilities, and commitment to safety during the interview.

To help you prepare and impress potential employers, we’ve compiled the top 30 commonly asked cable splicer interview questions along with tips and sample answers for acing each one. Read on to get insights into the types of questions you can expect, how to analyze and frame your responses, and examples to inspire your own winning answers. With these valuable resources, you’ll walk into your next interview fully ready to splice your way to success!

Overview of Common Cable Splicer Interview Questions

There are both technical and behavioral questions in cable splicer interviews. The behavioral questions are meant to test soft skills like communication, teamwork, and problem-solving. Here’s a quick overview of some frequent topics:

-

Technical knowledge Questions that test your understanding of cable splicing methods fiber optics network systems, tools/equipment, safety protocols, etc.

-

Experience: Questions about your specific work history, including projects you’re proud of and the kinds of splicing jobs you’ve done.

-

Troubleshooting skills: How you diagnose and resolve common splicing or network issues.

-

Communication abilities Explaining technical concepts clearly, collaborating with teams customer service.

-

Problem-solving/critical thinking: How you approach challenges, make decisions, and prioritize when issues arise.

-

Work ethic Questions gauging your professionalism, attention to detail, and commitment to safety and quality

Preparing responses and examples to address these common topics will ensure you’re poised to handle whatever questions come your way!

Now let’s explore the top 30 questions in detail:

Technical Questions

Technical interview questions allow you to demonstrate your hands-on expertise in cable splicing and showcase the specialized skills you’ve developed through training and experience. Be ready to get into specifics when answering these types of questions.

1. What experience do you have with fiber optic cable splicing?

This question is asked to determine your skill level and comfort working with fiber optics, a major aspect of most cable splicer roles. Emphasize your hands-on experience and technical knowledge.

Sample Answer: I have over 5 years of experience splicing and testing fiber optic cables. I’m highly proficient with fusion splicing techniques as well as connecting and troubleshooting multi-mode and single-mode fiber links. Safety is always my top priority when handling fiber optic cable components.

2. How do you troubleshoot issues that arise during splicing operations?

Employers want to know you have the expertise to quickly diagnose and resolve problems in the field. Demonstrate your technical troubleshooting process.

Sample Answer: When troubleshooting splicing issues, I’ll first conduct a visual inspection of all the equipment and connections to check for anything loose or damaged. Then I’ll test the cables and isolate the fault using an OTDR. If I locate a damaged section, I’ll cut it out and resplice the cables. I’ll repeat the process until the issue is fully resolved.

3. What safety precautions do you take when splicing cables?

Splicing cables comes with serious safety risks. Outline the protective steps you take to mitigate hazards and work safely.

Sample Answer: I always wear protective gear like safety glasses, insulated gloves, and fire-retardant clothing when splicing. I ensure my tools are properly insulated against electric shocks. When working at heights, I use fall protection harnesses anchored to stable structures. I also adhere to lockout/tagout procedures when handling live cables. Safety is my top concern.

4. What tools and equipment are important for splicing cables?

Hiring managers want to know you have experience with the key tools needed to perform splicing work properly. Showcase this expertise in your answer.

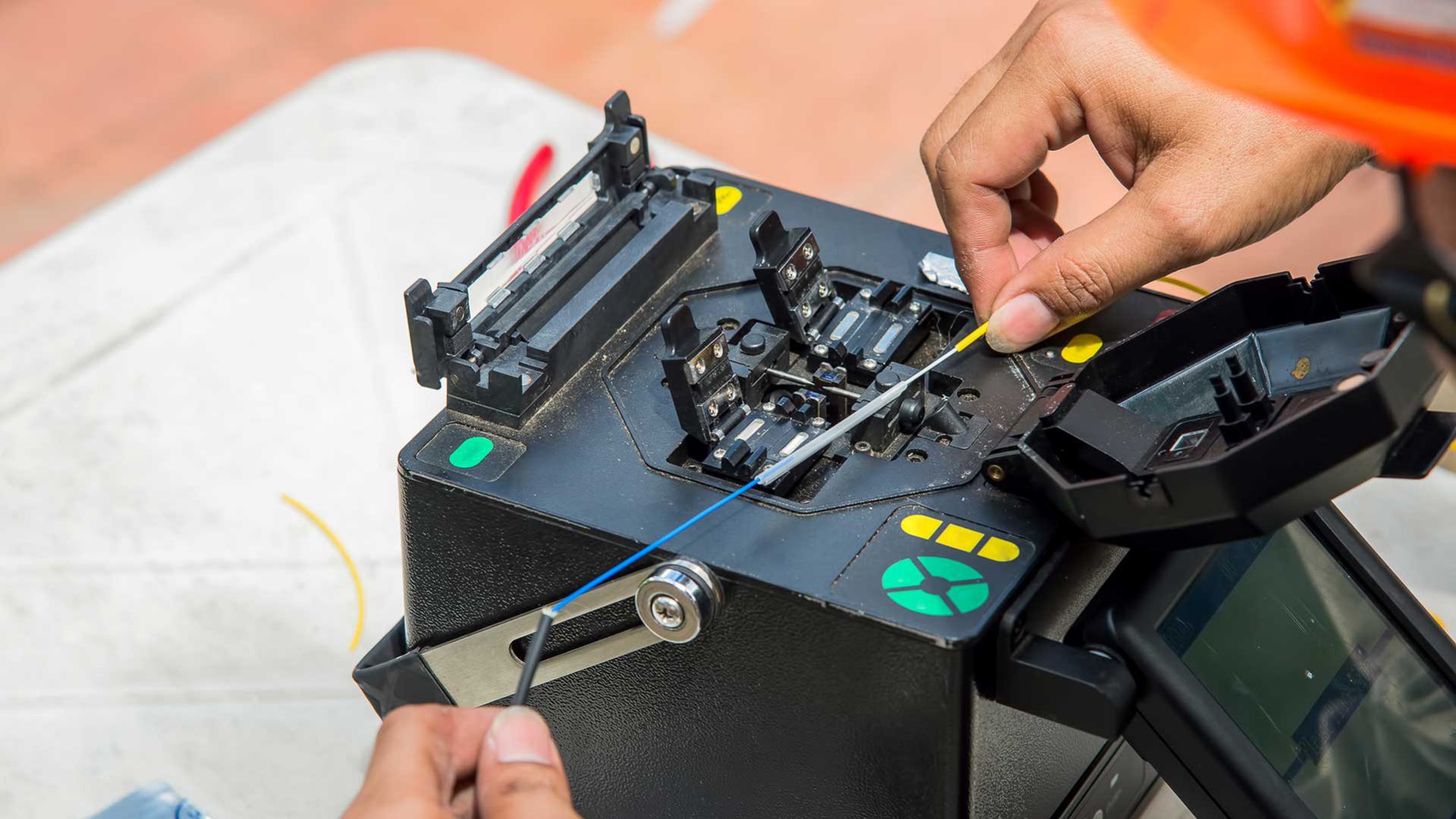

Sample Answer: Important tools I use in cable splicing include wire strippers, cable shears, crimping tools, and insulation knives for cable preparation. Fusion splicers, cleavers, and mechanical splices join and align the cable ends. I also rely on testing tools like OTDRs, light meters, multimeters, and cable certifiers to validate signal integrity and continuity.

5. How do you inspect and prepare cable ends for splicing?

This question tests your knowledge of fundamental splicing steps like cable preparation. Highlight your hands-on skills.

Sample Answer: Proper inspection and preparation ensures secure, lasting splices. I first examine the cable jacket for defects. Then I strip back a specified length of the jacket to access the wires inside. Each wire is cleaned, straightened, and trimmed to leave an undamaged, uniform end. I keep fiber optics clean and use index matching gel. This prepares the wires for precision joining.

6. Explain how you would splice a fiber optic cable.

Interviewers want to understand your specialized knowledge of working with fiber optics. Walk them through the step-by-step process.

Sample Answer: To splice fiber optic cables, I first examine the interior of the jacket for fiber count and arrangement. I strip the jacket using the proper tools, then carefully clean the exposed fiber ends. After placing the prepared fibers into a fusion splicer, I ensure their ends are flush and cleanly cleaved. The fibers are aligned using the splicer’s electrodes and fused together. Finally, I protect the joint and test the splice for continuity using an OTDR.

7. How do you test and validate your splicing work?

Thorough testing ensures you deliver quality splices. Share testing best practices that reinforce your technical expertise.

Sample Answer: Once a splice is completed, I visually inspect it to ensure proper joins. For copper splicing, I’ll use a multimeter to test continuity. For fiber optics, I use an OTDR to measure signal loss and analyze the splice profile. I also perform cable certification testing on longer segments. If issues are detected, I re-splice and retest until optimal performance is achieved.

8. How would you explain splicing concepts to someone without a technical background?

As a cable splicer, you may need to communicate complex technical details to non-technical audiences. This question assesses those skills.

Sample Answer: I would explain that splicing involves connecting the individual wires inside cables together to complete an electrical or data circuit. Splices allow signals to pass from one cable segment to another. I would use simple analogies, like splicing being similar to connecting pieces of string together. I would also utilize diagrams and active listening to ensure my explanations are clear and tailored to their level of understanding.

Experience-Based Questions

When interviewers ask about your experience, they want to understand the specific skills you’ve gained in past cable splicer roles. Focus on quantifying your exposure to projects relevant to their needs.

9. Tell me about your experience splicing copper cables.

With this question, highlight your hands-on expertise working specifically with copper cable systems. Provide details of tasks performed.

Sample Answer: I have spliced thousands of copper cables for telephony and low-voltage systems over my career. This includes direct-bury splices for underground networks using heat-shrink tubing. In exchange environments, I’ve used punch-down blocks extensively for copper terminations. I have experience with 25-pair and 50-pair splicing and testing using specialized tools.

10. Could you walk me through the process of an aerial fiber optic cable splice?

Share a specific example that quickly proves your technical know-how and ability to execute an aerial fiber optic splice successfully.

Sample Answer: For an aerial splice, I would bring my bucket truck onsite and ascend with the required tools and equipment. At the pole, I would isolate the damaged section of fiber to be spliced and prepare the ends, cleaning and cleaving the fibers properly. Next, I would fusion splice the ends together within a splice enclosure, securing it to the strand. Once completed, I would test the splice using an OTDR and other tools to ensure no signal loss before closing up the job.

11. What was the most complex splicing project you worked on? How did you handle it?

Complex projects really test a cable splicer’s skills. Recount a challenging splicing scenario and how you managed it to demonstrate your abilities under pressure.

Sample Answer: The most complex project was replacing deteriorated copper splices in a 50-year-old telephone exchange building. With over 10,000 copper pairs to resplice and a tight deadline, careful planning was crucial. I led a team to methodically segment and document each cable rack for improved organization. We utilized multiple splicing stations and techs performed quality checks of each other’s work to ensure accuracy. My coordination and technical expertise allowed us to complete the project on time.

12. Have you handled fiber optic cable splicing projects in harsh or hazardous environments?

If the job requires splicing in tough conditions, share examples of your experience meeting the challenge while following safety protocols.

Sample Answer: Yes, I have significant experience splicing fiber in harsh industrial environments with live electrical hazards and dangerous heights. Safety is always the priority.

Best Fiber Splicer Interview Tips | Give 5 Answers and Get Selected | Fiber Technician Interview

FAQ

What questions are asked in a cable management interview?

What does a cable splicer do?

How much do wire splicers make?

|

|

Annual Salary

|

Monthly Pay

|

|

Top Earners

|

$68,000

|

$5,666

|

|

75th Percentile

|

$57,500

|

$4,791

|

|

Average

|

$57,183

|

$4,765

|

|

25th Percentile

|

$44,000

|

$3,666

|

How do I prepare for a cable technician interview?

But first, you have to make it through the interview process. That means preparing for questions specific to the role of a cable technician—and knowing how to answer them clearly, confidently, and accurately. To help you get started, we’ve put together this list of common cable technician interview questions.

What questions do interviewers ask about cable installation?

Cable installation is a customer-facing job, so it’s important to understand how well you can handle customer service. By asking this question, interviewers are looking to get a sense of how you deal with customers who are not satisfied with your work. Do you take responsibility for any mistakes you’ve made?

Why do cable technicians ask a question?

Cable technicians need to keep up with the latest industry standards and regulations in order to do their job effectively. This question is a way for the interviewer to gauge your knowledge and make sure you’re up-to-date on the most important aspects of the job.

What skills do cable technicians need?

Cable technicians need to have a deep knowledge of different cable systems and the tools and processes used to install and troubleshoot them. This question is designed to gauge your technical expertise and assess your ability to think on your feet and troubleshoot any issues that arise. How to Answer: