Landing a job as a simulation engineer requires impeccable technical skills and the ability to handle complex modeling projects However, before you can put your expertise to work, you need to ace the interview

Having well-thought-out answers ready for common simulation engineer interview questions can make or break your chances of getting the job. We give you important examples and writing tips in this detailed guide to help you write winning answers.

1. Walk Me Through Your Experience With Computational Fluid Dynamics

Computational fluid dynamics (CFD) is an essential simulation technique in many engineering domains. Interviewers ask this to assess your hands-on expertise and problem-solving skills.

In your response, provide a specific example of a project where you leveraged CFD Explain your approach to setting up the model, the tools used, and the insights gained Emphasize your understanding of fluid dynamics principles and ability to apply CFD to solve complex real-world problems.

“In a recent project, I used CFD to make the drone’s aerodynamic design better.” I first created a CAD model of the drone’s geometry. I used ANSYS Fluent to create a transient turbulence model with dynamic meshing to see how air moves around the moving parts. This provided details on pressure distribution and drag forces. The simulations revealed certain design flaws that were causing excessive drag. We were able to increase the aerodynamic efficiency by over 15% by studying optimization and making changes to the model over and over again. “.

2. How Do You Ensure Your Simulations Remain Scalable?

Scalability is key to developing versatile simulation models that can adapt to various scenarios. Interviewers want to know your strategies for building flexible, future-proof models.

In your answer, highlight techniques like modular design, robust testing under extreme conditions, cloud computing, and optimization for parallel processing. Demonstrate how you anticipate and address scalability challenges proactively.

Example: “To ensure scalability, I focus on modular model architecture right from the design phase. I also leverage cloud-based solutions which provide flexibility to scale simulations up or down based on complexity. Testing under extreme scenarios identifies bottlenecks early on. Additionally, I optimize code for parallel execution and use parameterized inputs. This combination helps create nimble models that can be rapidly adapted for different applications.”

3. How Do You Validate Your Simulation Models?

Model validation is crucial for reliability. Interviewers will assess your rigor and expertise in this critical process. Discuss your use of real-world data comparison, cross-validation techniques, and uncertainty quantification. Convey your attention to detail and commitment to producing trusted simulation outcomes.

Example: “I use a combination of methods to thoroughly validate models. First, I compare simulation outputs with experimental data to quantify accuracy. I also do partition analysis by dividing data into training and validation sets to avoid overfitting. Additionally, I perform uncertainty quantification using Monte Carlo simulations to create confidence bounds on predictions. My goal is to ensure our clients can trust the models to make decisions and predict performance accurately.”

4. Tell Us About a Time You Detected and Resolved Simulation Errors

Things can often go awry in complex modeling projects. Interviewers want to know how you methodically troubleshoot issues. Walk them through how you identified anomalous outputs, traced sources of error, and implemented fixes. Showcase analytical abilities and sound technical knowledge.

Example: “In a recent automotive aerodynamics project, the drag coefficient results from our CFD model were not aligning with wind tunnel tests. By going back and double-checking inlet conditions, I found that upstream pressure values in the simulation were incorrect. Fixing this immediately improved correlation. It underscored the importance of thoroughly validating inputs before drawing conclusions about outputs.”

5. What Engineering Software and Tools Are You Skilled With?

Simulation engineers must be adept at using various software packages. Interviewers will assess your exposure to industry-standard programs. Highlight expertise with tools like MATLAB, Simulink, COMSOL, ANSYS, SolidWorks, and any scripting languages. Include specific examples of projects where you applied these skills.

Example: “I have extensive experience with ANSYS for structural, thermal and flow simulations. I also have working knowledge of STAR-CCM+ and fluent CFD tools. Additionally, I am proficient with MATLAB for modeling and post-processing. I employ tools like Simulink and COMSOL for controls, electromagnetic simulations. Python enables me to automate workflows. These skills were honed through hands-on work on aerospace, automotive, and electronics projects.”

6. How Do You Optimize Simulation Computational Efficiency?

Large simulations require substantial compute power. Interviewers want to know how you maximize efficiency. Discuss strategies like using efficient numerical methods, variable time-stepping, parallelization, caching/re-using data, and hardware acceleration with GPUs. Convey resourcefulness in optimizing performance within project constraints.

Example: “Several techniques help optimize computational efficiency. I apply variable time-stepping to focus computations during transients. Parallelizing workflows splits load over multi-core processors. Code profiling identifies optimization hotspots. Caching avoids redundant calculations. I also take advantage of GPU acceleration for matrix-heavy operations. Lastly, I use efficient implicit solvers where possible. These strategies help speed up simulations significantly while managing resources prudently.”

7. How Have You Applied Machine Learning In Your Work?

As simulation models grow in complexity, machine learning is an increasingly crucial tool. Interviewers want to understand your hands-on experience and creative thinking in leveraging AI. Provide examples of using ML techniques like surrogate modeling, design exploration, model reduction, and parameter optimization.

Example: “I have used ML extensively to enhance simulation workflows. For an aircraft wing design project, I trained a convolutional neural network on CFD results to predict drag coefficients for new geometries. This allowed rapid design iterations. I have also employed ML to select optimal turbulence models based on data patterns. Additionally, surrogate ML models have enabled inexpensive what-if scenario testing for designs.”

8. How Do You Maintain Clear Documentation For Simulation Models?

Thorough documentation is essential for replicability and future enhancement of simulations. Interviewers want to know your approach to keep records organized and consistent. Discuss your use of version control systems, detailed comments, standard templates, model diagrams/flowcharts, and maintenance of detailed build/run manuals. Demonstrate appreciation for meticulous documentation practices.

Example: “Maintaining clear documentation ensures seamless handover and future-proofs simulation investments. I document code extensively with comments outlining intent and approach. Standard templates provide consistency in model reports. I use Git to maintain version control and track changes. Flowcharts/diagrams provide visual representation of model logic. Detailed build manuals capture hardware, software, parameter settings required to recreate the environment.”

9. How Do You Stay Current On Simulation Technologies and Methodologies?

The field evolves constantly, making learning agility important. Interviewers want to see that you take initiative to upgrade your skills. Share how you take advantage of resources like conferences, research papers, certifications, tech blogs, MOOCs, and training programs. Demonstrate self-motivation for continuous improvement.

Example: “I make conscious efforts to stay updated on simulation technologies. I regularly read research papers and textbooks to expand my knowledge. I also attend industry conferences like SAE World Congress to hear applied presentations. Online courses on platforms like Udemy allow me to learn new software packages. Following thought leaders and communities of practice exposes me to emerging methods. These activities help me enrich my skills and apply cutting-edge simulation techniques.”

10. Talk About a Time You Had To Make Trade-Offs Between Simulation Fidelity and Computational Cost

Designing simulations involves balancing model complexity with practical project constraints like time and resources. Interviewers will present you with such situations to assess your judgment. Explain how you justified and made sound compromises, while preserving acceptable accuracy.

Example: “In an automotive CFD project, we had severe time limitations. High-fidelity turbulent flow simulations were unfeasible within the deadline. By consulting with domain experts, I made reasonable simplifications like using steady RANS instead of transient LES modeling. This achieved sufficient accuracy for design decisions, at a fraction of the compute cost. It taught me to pragmatically optimize fidelity to constraints.”

11. How Do You Integrate Simulations Within Overall Product Development Workflows?

Simulations cannot occur in isolation. Interviewers want to understand your big-picture thinking in aligning modeling activities with engineering design and testing processes. Discuss how you facilitate cross-functional collaboration, iterative exchanges, and seamless data sharing between simulation and other teams.

Example: “I work closely with design and test engineers in a collaborative loop. We exchange CAD models, performance data, and parameters to continuously improve the product. I provide simulation feedback at each iteration to guide designs. Physical test results help validate and enhance models. My team also works upstream with requirements analysts to align simulations with product goals. This integration allows rapid, informed engineering decisions.”

12. Tell Us About a Time You Had To Learn a New Simulation Tool or Technique Quickly

The dynamic nature of the field requires learning agility even when working against tight deadlines. Share an example that demonstrates your capacity to rapidly skill up. Discuss how you used documentation, training courses, and manufacturer

Interviewing as a Process EngineerEmbarking on the journey to secure a role as a Process Engineer involves navigating through a series of interviews that test not only your technical expertise but also your analytical thinking and problem-solving skills. Process Engineers are the backbone of operational efficiency, and their interviews reflect the multifaceted nature of their responsibilities. In this guide, we’ll dissect the array of questions that you, as a Process Engineer candidate, should anticipate. From probing your understanding of process design and optimization to evaluating your ability to manage projects and work collaboratively across departments. We’ll provide you with the tools to craft compelling responses, share insights on the hallmarks of an exceptional candidate, and suggest strategic questions to pose to your potential employers. Our aim is to arm you with the knowledge and confidence required to excel in your interviews and propel your career forward as a Process Engineer.

- Review Core Engineering Principles: Go over basic engineering ideas like thermodynamics, fluid mechanics, and material science again. These are often the basis for technical questions.

- Learn About the Company’s Products and Processes: Find out about the company’s manufacturing methods, the products they make, and the problems they face in their industry. This will help you make your answers fit the situation.

- Learn About Useful Process Engineering Software and Tools: Get to know process simulation software and tools like HYSYS, Aspen Plus, or MATLAB that are commonly used in the field, and be ready to talk about how well you know how to use them.

- To get ready for behavioral questions, think about projects and situations from the past where you used your process engineering skills. Get ready to talk about these events and what you learned from them.

- Learn more about project management and lean principles. Process engineers work on a lot of projects that need good management and lean operations. It can be very helpful to know about project management frameworks and lean methodologies.

- Put together a portfolio of your work. If you can, bring examples of your work, like process diagrams, P

- Prepare Thoughtful Questions: Write down some questions that show you’re interested in the company’s upcoming projects, process problems, and what they expect from you in this role.

- Do mock interviews. Work on your ability to communicate your ideas clearly and professionally by practicing with a friend or mentor. This can also help alleviate interview anxiety.

By following these steps, youll be able to enter the interview with confidence in your abilities and a clear understanding of how you can contribute to the companys objectives. Remember, the goal is not just to answer questions, but to engage in a dialogue that positions you as a valuable asset to the team.

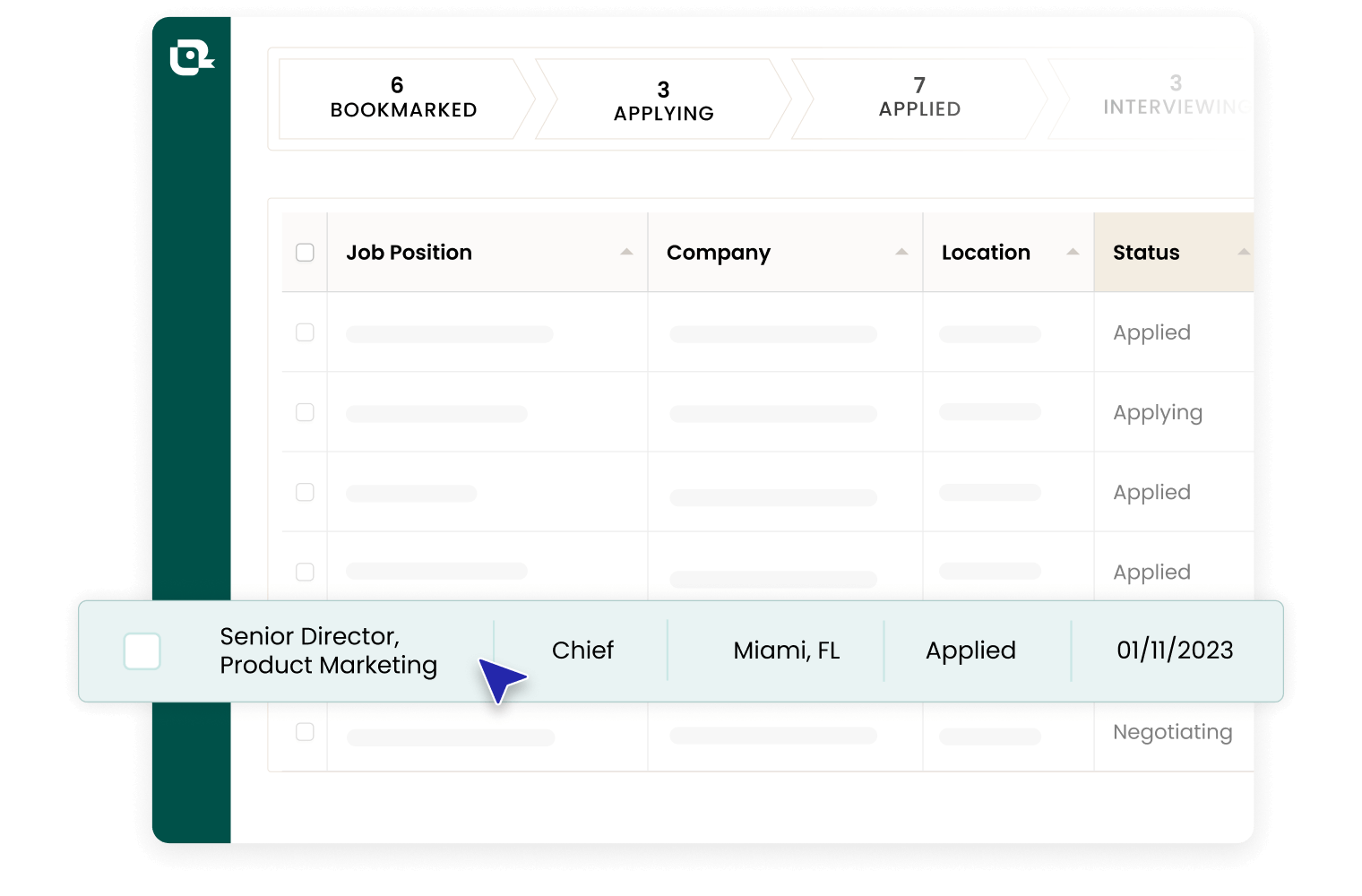

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Interview Simulation

FAQ

What is the role of a simulation engineer?

What qualifications do you need to be a simulation engineer?

What are the 3 questions an engineer has to ask?

What is the role of process simulation engineer?

What are the most common simulation engineer interview questions?

Most interviews will include questions about your personality, qualifications, experience and how well you would fit the job. In this article, we review examples of various simulation engineer interview questions and sample answers to some of the most common questions. Common Simulation Engineer Interview Questions

What questions should I ask during a modeling & simulation interview?

Here are 20 commonly asked Modeling and Simulation interview questions and answers to prepare you for your interview: 1. What is a system model? A system model is a simplified representation of a system that is used to aid in understanding the system.

Why should you ask a simulation engineer a job interview?

This question is a great way for hiring managers to gauge your practical experience and problem-solving skills. A simulation engineer’s role often involves dealing with complex projects, requiring not only technical knowledge but also a strategic approach to project management.

What are interviewers looking for from a simulation specialist?

Learn what skills and qualities interviewers are looking for from a simulation specialist, what questions you can expect, and how you should go about answering them. Simulation specialists create models that help organizations understand complex systems and make better decisions.