Securing a job in supply chain procurement requires strong interview skills. These roles demand a complex mix of technical know-how analytical thinking, negotiation abilities and business acumen. This makes the interview process particularly rigorous.

Hiring managers want to ensure candidates have what it takes to navigate the intricate world of global supply chains. They need strategic thinkers who can optimize costs, build relationships, drive innovations, and deal with uncertainties.

To assess these competencies, interviewers will pose a range of situational, behavioral and technical questions. Having compelling responses ready is key to making it through to the next round.

To help you put your best foot forward, here are 30 common supply chain procurement interview questions along with sample answers:

Situational Questions

Situational questions test your problem-solving skills and analytical thinking in complex, real-world scenarios. They give you an idea of how you might handle the day-to-day challenges of procurement roles.

1. How would you handle a sudden increase in demand for a product or service?

In response to a sudden increase in demand, I would first assess our current inventory and production capacity. If necessary, I’d expedite orders or increase production schedules. Simultaneously, I’ll communicate with suppliers to ensure they can meet the increased demand. If not, exploring alternative sources is crucial to prevent supply chain disruptions. Furthermore, I would collaborate with sales and marketing teams to manage customer expectations regarding delivery timescales.

2. How do you ensure the continuous supply of materials and prevent shortages in a volatile market?

In a volatile market, it’s important to have strong forecasting and demand planning systems in place to make sure there is a steady supply of materials. This allows for accurate prediction of required quantities, helping prevent shortages. Diversifying the supplier base is another key strategy. Because they don’t depend on a single source, the chance of a disruption is much lower. Putting in place real-time tracking systems can also give you a clear picture of the supply chain, so you can respond quickly to any problems that might arise.

3. What steps do you take to mitigate risks in the supply chain?

To mitigate risks in the supply chain, I focus on diversifying suppliers to avoid dependence on a single source. This includes identifying alternative vendors and establishing relationships with them. I also prioritize transparency throughout the supply chain by implementing real-time tracking systems. These can provide early warning signs of potential disruptions, allowing for proactive risk management.

4. How do you handle a situation where a supplier consistently fails to meet quality or delivery standards?

In such a situation, I would first communicate with the supplier to understand the root cause of these issues. If it’s a solvable problem, we can work together on an improvement plan. However, if there’s no significant progress over time, it may be necessary to consider other suppliers. It’s crucial to maintain high standards for quality and delivery in order to satisfy our customers’ needs and expectations. Throughout this process, I’d ensure all actions align with company policies and contractual obligations.

Technical Questions

Technical questions evaluate your knowledge and experience with the practical aspects of procurement like sourcing, vendor management, systems, and tools. Your responses will showcase your capabilities and expertise in the field.

5. What methods do you use to forecast demand and determine order quantities?

I primarily use quantitative methods for demand forecasting. This includes time series analysis, where I analyze historical data to identify trends and seasonality patterns. For determining order quantities, I employ the Economic Order Quantity (EOQ) model which balances ordering cost against holding costs. Moreover, I also consider qualitative factors such as market intelligence or changes in industry regulations that could impact future demand.

6. Could you discuss your experience with global sourcing and managing international suppliers?

I have extensive experience in global sourcing, having worked with suppliers from various regions including Asia, Europe and South America. This involved negotiating contracts, ensuring quality control, and managing logistics. Understanding cultural nuances was crucial for effective communication and building strong relationships. I had to adapt my approach depending on the supplier’s location and business practices.

7. What is your approach to supplier development and performance improvement?

My approach to supplier development involves building strong, collaborative relationships. This includes regular communication and feedback sessions to understand their capabilities and areas for improvement. Performance improvement is a continuous process. I believe in setting clear expectations and KPIs from the start. Regular performance reviews are essential to identify gaps and address them promptly with corrective actions.

8. Could you discuss your experience with e-procurement systems?

I have extensive experience with e-procurement systems, having utilized them to streamline purchasing processes and improve efficiency. I’ve worked with SAP Ariba and Coupa, using their features for supplier management, contract management, and spend analysis. In one instance, I led a team in implementing an e-procurement system that reduced procurement cycle times by 30%.

Behavioral Questions

Behavioral questions evaluate your soft skills like communication, relationship-building, ethics, and crisis management. Your responses should demonstrate these competencies with real examples.

9. Can you describe a situation where you successfully negotiated a contract with a supplier?

In one instance, I was tasked with negotiating a contract with a key supplier. The initial offer was above our budget and had an extended delivery timeline. I conducted a comprehensive market analysis to understand the average cost and lead time for similar products. This data helped me present a counteroffer that was competitive yet within our budget. Simultaneously, I emphasized on our long-term relationship and future business opportunities. After several rounds of negotiation, we agreed on a price 20% lower than the original quote and reduced the lead time by two weeks.

10. What strategies do you employ to maintain relationships with suppliers?

Maintaining relationships with suppliers is crucial in supply chain procurement. I employ a proactive communication strategy, ensuring regular check-ins and updates to keep both parties informed of any changes or issues. Understanding their business needs and constraints is another key aspect. This allows for mutual respect and understanding, leading to stronger partnerships.

11. How do you handle ethical issues in procurement?

In handling ethical issues in procurement, I always adhere to the organization’s code of conduct and procurement policies. For instance, if a supplier offers a personal incentive to secure a contract, I would decline it immediately and report to my superior. Transparency is also key. If there are any conflicts of interest or potential bias in supplier selection, I ensure they are disclosed upfront.

12. How have you handled a situation where key stakeholders had conflicting requirements?

When faced with conflicting requirements, I prioritize open communication and collaboration. I would facilitate a meeting with the stakeholders to understand their perspectives and clarify the objectives. Next, I’d analyze these requirements in relation to our supply chain strategy. The goal is to find a common ground that aligns with our business goals without compromising efficiency or cost-effectiveness.

Leadership Questions

Leadership questions evaluate your strategic thinking, change management skills, and ability to drive innovations and improvements in the procurement function.

13. Can you share your experience with implementing a new procurement system or process?

In a previous project, I led the implementation of a cloud-based procurement system to streamline purchasing. The first step was understanding our needs and identifying the right software. After selecting the software, I coordinated with IT for integration. Training staff on the new system was crucial. We conducted workshops and provided resources to ensure everyone was comfortable using it. The result was a 30% reduction in processing time and improved vendor relationships due to better communication.

14. What strategies have you used to manage and reduce lead times?

In managing and reducing lead times, I’ve found that effective communication with suppliers is crucial. Regular updates on demand forecasts can help them plan their production schedules more efficiently. Implementing a vendor-managed inventory system has also been beneficial. This allows the supplier to monitor stock levels in real-time and replenish as needed, reducing the risk of stockouts and excess inventory.

15. How would you handle a supplier who is reluctant to share information necessary for effective supply chain management?

Building a relationship based on trust and mutual benefit is crucial when dealing with suppliers. If a supplier is reluctant to share information, I would emphasize the importance of transparency for efficient supply chain management and how it can lead to improved business outcomes for both parties. If reluctance persists, I’d propose a non-disclosure agreement to assure them that their sensitive information will not be misused.

Analytical Questions

Analytical questions test your problem-solving abilities, data interpretation skills, and logical thinking. Procurement professionals must leverage data insights to make smart decisions so expect these types of questions.

16. What is your approach to cost reduction in the procurement process?

My approach to cost reduction in procurement is multifaceted. I believe in leveraging technology for process automation, which reduces manual errors and saves time. Negotiating with suppliers for better prices and payment terms is also crucial. I emphasize the importance of analyzing spend data to identify patterns and areas where costs can be reduced. This could involve consolidating purchases or choosing alternative suppliers. Implementing a strategic sourcing process is another method, allowing us to select suppliers who provide the best value, not just the lowest price.

17. How do you ensure the accuracy of procurement data and reports?

To ensure the accuracy of procurement data

Interviewing as a Procurement SpecialistNavigating the path to becoming a Procurement Specialist involves more than just understanding supply chains and cost-saving strategies; it requires demonstrating your expertise during the interview process. As gatekeepers of organizational spending, Procurement Specialists must exhibit a keen analytical mind, strong negotiation skills, and a comprehensive grasp of procurement ethics and vendor management. Our guide is meticulously crafted to prepare you for the multifaceted interview questions you’ll face. We’ll dissect the significance of each question type, from behavioral to case studies, and provide insights into crafting responses that showcase your qualifications. We’ll also arm you with the knowledge of what interviewers seek in a top-tier candidate and the strategic questions you should ask to leave a lasting impression. This guide is your blueprint to mastering Procurement Specialist interviews, positioning you to secure your next role with confidence.

- Find Out What the Company Needs: Learn about the company’s supply chain, the industry it works in, and any problems it faces. This will help you make your answers more relevant to their needs and show how your skills can meet those needs.

- Read over the latest procurement software, e-procurement systems, and supply chain management tools to get a feel for the latest procurement processes and tools. Talk about any similar systems you’ve worked with before and how well you can learn new technologies.

- For the behavioral questions, think about the times you’ve handled supplier relationships, negotiated contracts, or saved money. Give specific examples from your past experiences. Set the tone for your answers with the STAR method (Situation, Task, Action, Result).

- Know About Legal and Moral Issues: Buying things often means figuring out tricky legal and moral situations. Prepare to talk about how you handle these kinds of situations and follow the laws and rules that apply.

- Prepare Your Questions: Think of thoughtful questions that show you understand the company’s procurement strategies and are interested in them. For example, you could ask about their supplier diversity programs or environmentally friendly purchasing practices.

- Negotiation Practice: You might be asked to act out a negotiation situation. You can show off your negotiation skills and ability to stay calm and convincing under pressure by practicing these situations ahead of time.

- Review Procurement Trends and Best Practices: Know about the newest procurement trends, like risk management, digital transformation, and sustainable sourcing. Talking about these issues will show that you are dedicated to strategic development and continuous improvement.

By following these steps, youll demonstrate not only your expertise in procurement but also your strategic alignment with the companys goals and your potential to be a valuable asset to their team. Your preparation will shine through in your confident and informed responses, setting you apart from other candidates.

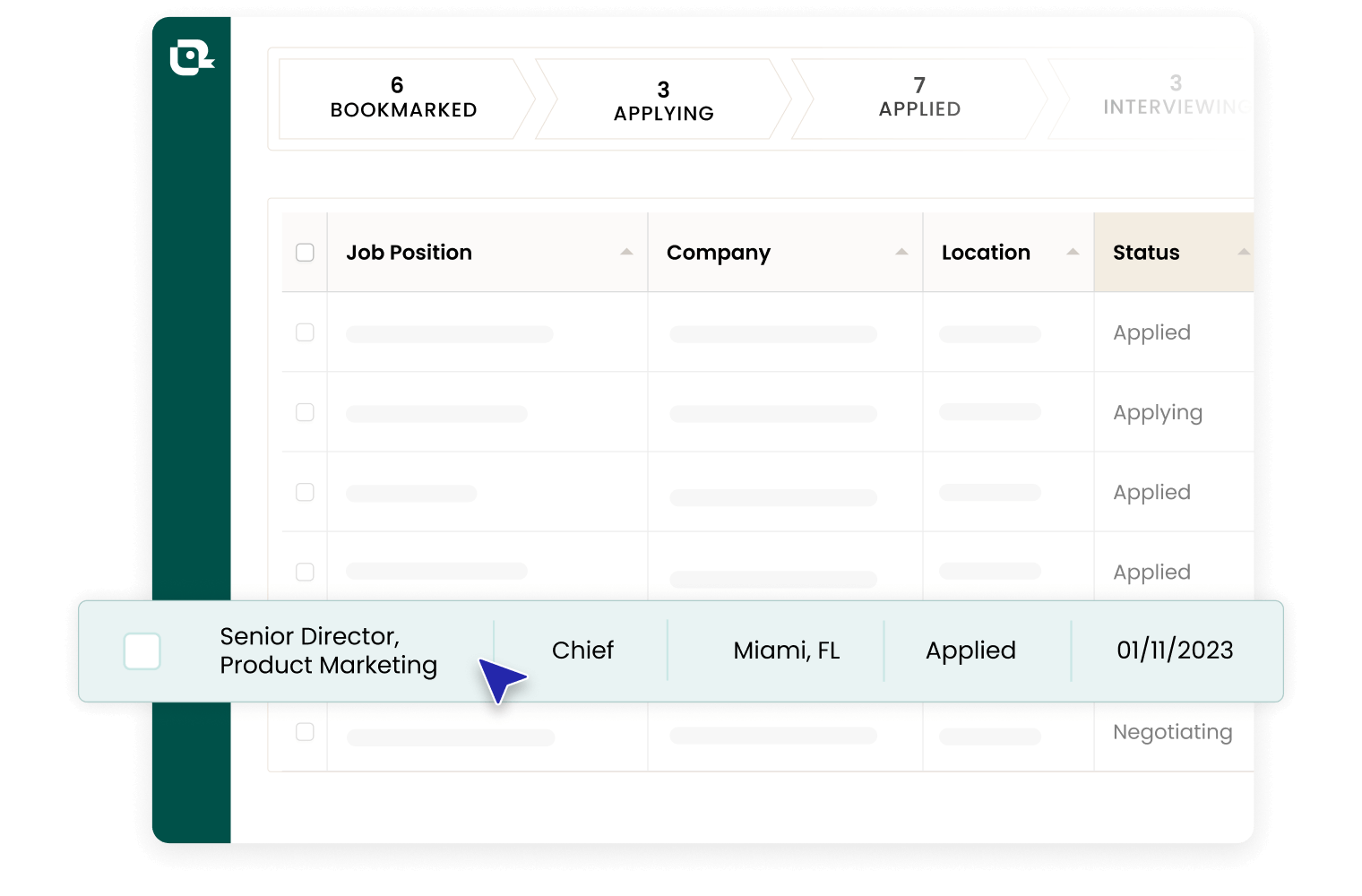

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

PROCUREMENT OFFICER Interview Questions And Answers!

Are you prepared for a supply chain procurement interview?

If you’re pursuing a career in this challenging yet rewarding field, it’s essential to be well-prepared for your upcoming interview. To help you demonstrate your expertise and make a lasting impression on potential employers, we’ll explore common questions asked during interviews for supply chain procurement roles.

What should you expect in a supply chain management interview?

Supply chain management roles can range from sourcing to logistics to product development. During the interview, demonstrate your leadership skills, supply chain software knowledge and experience working with suppliers. In this article, we’ll share 20 supply chain management interview questions with sample answers.

How do you answer a job interview question about procurement?

While the employer is interested in your experience, they are also interested in your skills and exploring your background. When answering the question, consider the skills necessary in procurement and try incorporating them into your answer.

How many supply chain interview questions are there?

Supply chain interview questions vary based on an applicant’s experience level. The article presents a diverse set of 27 supply chain interview questions, ranging from fundamental concepts to situational problem-solving. Are you looking for supply chain interview questions so you can gain the edge during your next interview?