Interviewing for a process development engineer role? This critical position is at the heart of taking a product from initial concept to full-scale manufacturing Companies rely on process development engineers to optimize and streamline production methods.

The interview aims to assess your technical expertise, problem-solving abilities, and communication skills Standing out requires thorough preparation using the right strategies.

In this comprehensive guide, we’ll explore the 15 most frequent process development engineer interview questions We’ll provide sample responses and insider tips to help you craft winning answers Read on to learn proven techniques to showcase your capabilities and land the job.

1. Walk Me Through Your Experience with Process Design and Development

This open-ended question lets you give a brief outline of how well you know core process development competencies.

How to Answer:

- Provide an overview of your experience in process design, modeling, scale-up, and troubleshooting.

- Offer 1-2 examples of development projects you successfully executed from concept to completion.

- Discuss specific tools and methodologies utilized, such as process flow diagrams, Design of Experiments (DOE), or Failure Mode Effects Analysis (FMEA).

- Emphasize contributions and quantifiable results, including improved efficiency, reduced costs, or faster time-to-market.

Sample Answer: “In my current job, I was in charge of creating a new way to coat tablets, from the initial idea to pilot scale-up and then to full commercialization.” We used DOE to find the best coating formula and made process flow diagrams and P Thanks to my hard work, the coating process went 200% faster and met all quality and efficiency standards. “.

2. How Do You Determine the Critical Process Parameters for a New Process?

This question tests your understanding of how to identify factors that impact process performance and product quality.

How to Answer:

- Explain how you would use risk analysis tools like FMEA to pinpoint critical parameters.

- Discuss conducting design of experiments such as fractional factorials to isolate vital few inputs.

- Provide examples of key process parameters you’ve determined, such as temperature, pressure, flow rate, or concentrations.

- Emphasize a data-driven, methodical approach to recognizing inputs requiring tight control.

Sample Response: “I use techniques like design of experiments, quality risk assessments, and historical process data analysis to systematically identify critical parameters. For example, when developing a new tablet compression process, I utilized a two-level factorial DOE to determine that press speed, dwell time, and lubricant concentration were vital to tablet hardness and dissolution. I later implemented SPC control charts on those three inputs.”

3. How Do You Ensure a Process Design Aligns with Quality Requirements?

This question evaluates your understanding of quality management principles and their integration into process development.

How to Answer:

- Discuss incorporating quality checkpoints throughout the design phase, such as risk analysis, DOE optimization, and process capability studies.

- Explain how you integrate quality metrics into design review and approval milestones.

- Provide examples of quality requirements you’ve addressed, like yield, purity, or dissolution specifications.

- Emphasize a collaborative approach working alongside quality assurance groups.

Sample Response: “Throughout process design, I utilize tools like FMEA, design space development, and tolerance analysis to optimize quality outcomes. I collaborate closely with QA to establish critical quality attributes, then review designs to ensure capabilities meet specifications through tolerance stacking exercises. We also perform process qualification runs to confirm designs deliver required quality before progression to the next phase.”

4. How Do You Approach Scaling Up a Process from Pilot to Manufacturing Scale?

This question tests your expertise in navigating scale-up, one of the most challenging aspects of process development.

How to Answer:

- Outline a structured stage-gate approach for methodical scale-up through laboratory, pilot, and manufacturing scale trials.

- Discuss critical considerations such as equipment parameters, process controls, material handling, and batch size effects.

- Provide an example of a successful scale-up you orchestrated.

- Emphasize utilizing data from each stage to assess and optimize scale-dependent effects.

Sample Response: “When approaching scale-up, I develop a risk-based control strategy based on prior knowledge and pilot data. I evaluate equipment requirements, flow parameters, mixing dynamics, and material handling needs. I’ll run trials at progressively larger scales while monitoring critical quality attributes to catch issues early. For example, when scaling up a granulation process, I noticed increases in particle size variation at manufacturing scale. By optimizing mixing parameters and binder atomization, I maintained granule uniformity across all scales.”

5. How Do You Optimize a Process to Improve Efficiency and Throughput?

This question evaluates your skills in process analysis, troubleshooting, and enhancement.

How to Answer:

- Discuss process mapping tools to identify bottlenecks and quantitate waste.

- Describe analytical methods like root cause analysis and design of experiments to optimize performance.

- Provide examples of improvements you’ve implemented, like cycle time reductions or improved material flows.

- Emphasize continuous improvement mindset and data-driven decision making.

Sample Response: “I utilize process mapping techniques such as value stream mapping to fully understand flow and uncover opportunities for greater efficiency. I dig into problems through fishbone diagrams and 5 Whys analysis. Recently, I improved tablet press productivity by 15% by determining excessive changeover times as the root cause. By optimizing die setup and standardizing tooling, I reduced downtime between batches.”

6. Describe a Time When Your Process or Equipment Failed to Deliver the Required Results

This behavioral question tests your approach to troubleshooting and problem-solving.

How to Answer:

- Provide a specific example demonstrating a systematic, root cause driven approach.

- Discuss diagnostic steps taken, such as data analysis, hypothesis testing, and experimentation.

- Share how you corrected the issue and put preventions in place.

- Emphasize teamwork, continuous learning, and process improvements enabled by overcoming challenges.

Sample Response: “During scale-up trials of a mixing process, we faced significant variability in blend homogeneity. I led a focused effort to get to the root cause by first gathering mixing energy profiles and blend sample data. This revealed inadequate shear in larger scale vessels. By adjusting impeller configurations based on computational fluid dynamics models, I was able to optimize mixing and achieve the required uniformity across scales.”

7. How Do You Prioritize Tasks When Managing Multiple Process Development Projects?

This question reveals your time management, organization, and priority-setting skills.

How to Answer:

- Discuss utilizing project management tools like Gantt charts to schedule and sequence tasks.

- Explain setting clear milestones aligned to business objectives.

- Describe regularly assessing risks, resources, and critical paths to readjust priorities as needed.

- Share an example of how you decided project sequencing that maximized efficiency.

Sample Response: “When juggling multiple projects, I first work closely with stakeholders to align on project goals, critical milestones, and success metrics. I then create detailed project plans outlining all key activities and resource needs. I utilize daily standups and weekly reviews to reevaluate priorities based on stage gates, resource constraints, and risks. This approach enabled me to efficiently stagger three formulation projects by prioritizing lab trials first for the project with the closest regulatory deadline.”

8. How Do You Stay Current on the Latest Technologies, Tools, and Regulations in Process Development?

This question evaluates your commitment to continuously expanding your technical knowledge.

How to Answer:

- Discuss regularly reviewing academic and industry publications to learn about new innovations.

- Explain attending technical conferences and seeking out webinars and training opportunities.

- Describe setting Google alerts for news on regulatory changes or process technologies.

- Share an example of how you recently expanded your knowledge, skills, or tools.

Sample Response: “I make learning about new process technologies a daily habit. I read industry publications, attend virtual events like AAPS annual meetings, and participate in relevant LinkedIn groups to gain knowledge. For example, I recently completed an ASQ course on quality risk management to improve my FMEA skills. I also learn by networking with peers at other companies to share best practices.”

9. How Do You Ensure Process Developments Meet Safety and Environmental Regulations?

This question evaluates your working knowledge of safety and environmental compliance considerations.

How to Answer:

- Discuss integrating safety and sustainability initiatives from the start of development.

- Describe conducting hazard analyses and risk assessments to identify concerns early on.

- Provide examples of environmentally sound materials or practices you’ve incorporated.

- Emphasize having regulatory knowledge and/or collaborating closely with EHS groups.

Sample Response: *”Creating safe, eco-friendly processes is a top priority for me. I perform in-depth risk assessments when designing experiments to minimize hazards. I utilize green chemistry principles, like using non-toxic solvents. I conduct thorough reviews to comply with safety standards like NFPA 45 and environmental regulations like REACH. For instance, I recently opted to use an inherently safer ultrasonic reactor

Interviewing as a Process EngineerEmbarking on the journey to secure a role as a Process Engineer involves navigating through a series of interviews that test not only your technical expertise but also your analytical thinking and problem-solving skills. Process Engineers are the backbone of operational efficiency, and their interviews reflect the multifaceted nature of their responsibilities. In this guide, we’ll dissect the array of questions that you, as a Process Engineer candidate, should anticipate. From probing your understanding of process design and optimization to evaluating your ability to manage projects and work collaboratively across departments. We’ll provide you with the tools to craft compelling responses, share insights on the hallmarks of an exceptional candidate, and suggest strategic questions to pose to your potential employers. Our aim is to arm you with the knowledge and confidence required to excel in your interviews and propel your career forward as a Process Engineer.

- Review Core Engineering Principles: Go over basic engineering ideas like thermodynamics, fluid mechanics, and material science again. These are often the basis for technical questions.

- Learn About the Company’s Products and Processes: Find out about the company’s manufacturing methods, the products they make, and the problems they face in their industry. This will help you make your answers fit the situation.

- Learn About Useful Process Engineering Software and Tools: Get to know process simulation software and tools like HYSYS, Aspen Plus, or MATLAB that are commonly used in the field, and be ready to talk about how well you know how to use them.

- To get ready for behavioral questions, think about projects and situations from the past where you used your process engineering skills. Get ready to talk about these events and what you learned from them.

- Learn more about project management and lean principles. Process engineers work on a lot of projects that need good management and lean operations. It can be very helpful to know about project management frameworks and lean methodologies.

- Put together a portfolio of your work. If you can, bring examples of your work, like process diagrams, P

- Prepare Thoughtful Questions: Write down some questions that show you’re interested in the company’s upcoming projects, process problems, and what they expect from you in this role.

- Do mock interviews. Work on your ability to communicate your ideas clearly and professionally by practicing with a friend or mentor. This can also help alleviate interview anxiety.

By following these steps, youll be able to enter the interview with confidence in your abilities and a clear understanding of how you can contribute to the companys objectives. Remember, the goal is not just to answer questions, but to engage in a dialogue that positions you as a valuable asset to the team.

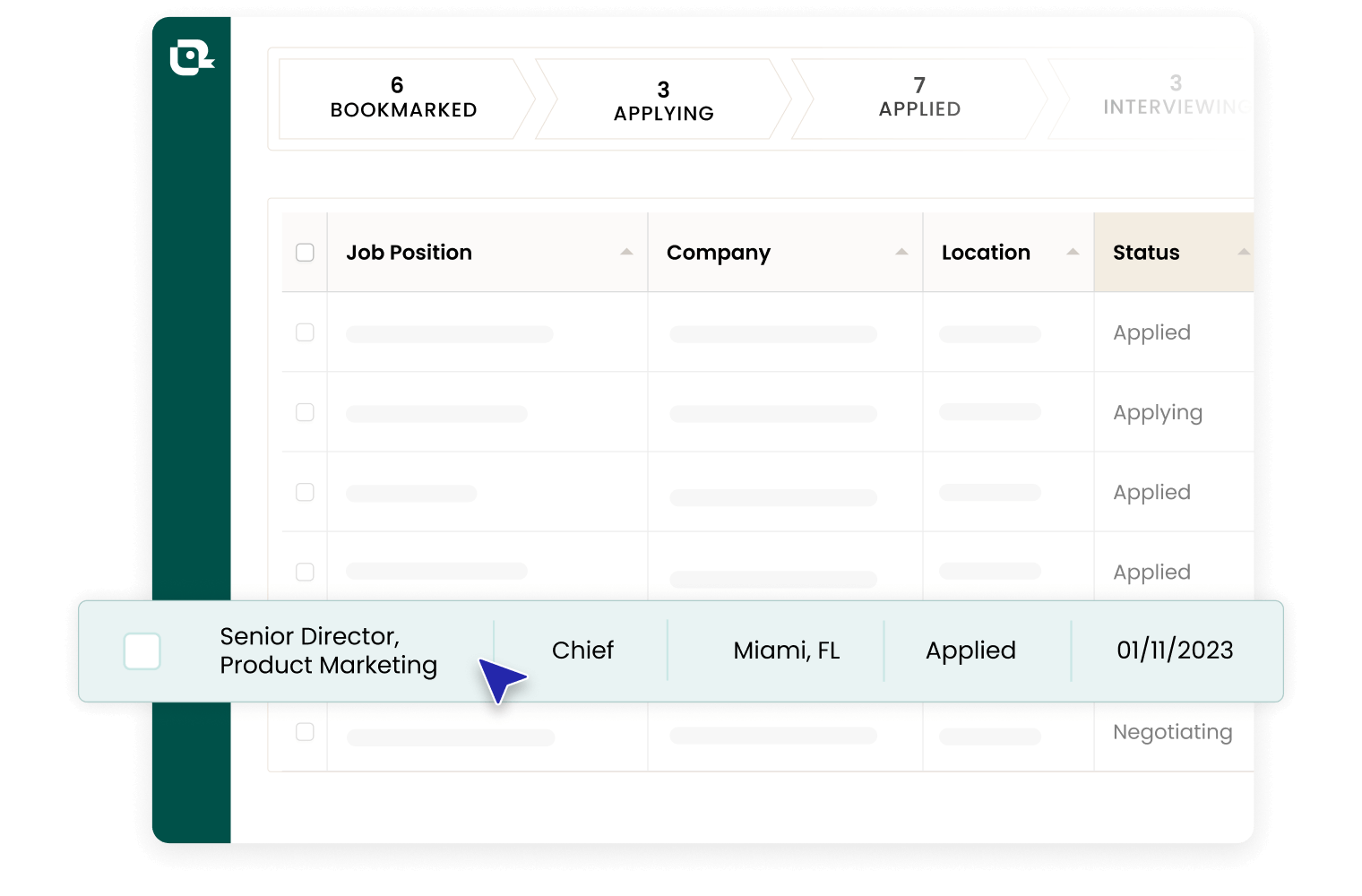

Stay Organized with Interview TrackingWorry less about scheduling and more on what really matters, nailing the interview. Simplify your process and prepare more effectively with Interview Tracking.

Process Development Engineer interview questions

FAQ

Why should we hire you as a process engineer?

What knowledge is needed for process engineer?

What is process engineering development?